SHUTTER COMPONENTS

Our fully integrated progressive GMC certified factory focuses on the quality that our shutter manufacturing customers demand. We know that straightness, smooth primed finish and long lengths are key ingredients that allow our customers to save time and money during the manufacturing process.

Our basswood is carefully dried in our kilns for 26 days to insure the highest stability, durability and straightness. Using the most advanced molders and sanders available in conjunction with our unique priming process allows us to consistently deliver the highest quality shutter components in today's market.

LOUVERS

2-1/2" x 7/16" Louver

3-1/2" x 7/16" Louver

4-1/2" x 7/16" Louver

STILES

2" x 1-1/16" Standard Stile

2" x 1-1/16" Rabbet Stile

2" x 1-1/16" Double Bead Rabbet Stile

5/8" x 1/2" Tilt Rod

RAILS

3" x 3/4" Divider Rail

4" x 3/4" Divider Rail

4-1/2" x 3/4" Top/Bottom Rail

5-1/2" x 3/4" Top/Bottom Rail

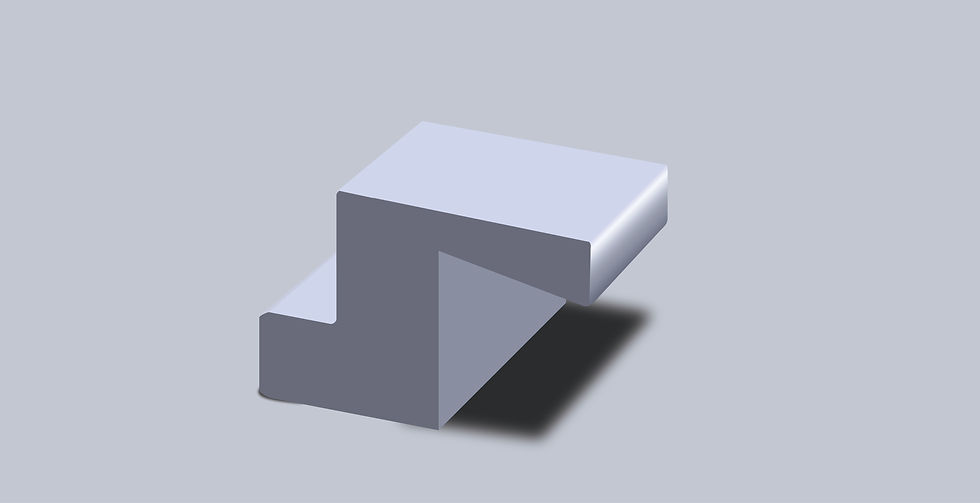

FRAMES

1-1/4" x 1-7/8" Box-out L-Frame

3/4" x 1-7/8" L-Frame

1-1/4" x 1-1/8" Hanging Strip

3/4" x 3/4" Light Stop

3" x 1-7/8" Flat Z-Frame

3" x 1-7/8" Regency Z-Frame

2" x 1-7/8" Museum Z-Frame

1-1/2" x 1-7/8" Bullnose Z-Frame

2" x 1-7/8" Flat Z-Frame

1-1/4" x 1-7/8" Z-Frame

1-1/2" x 1-7/8" Z-Frame